Description

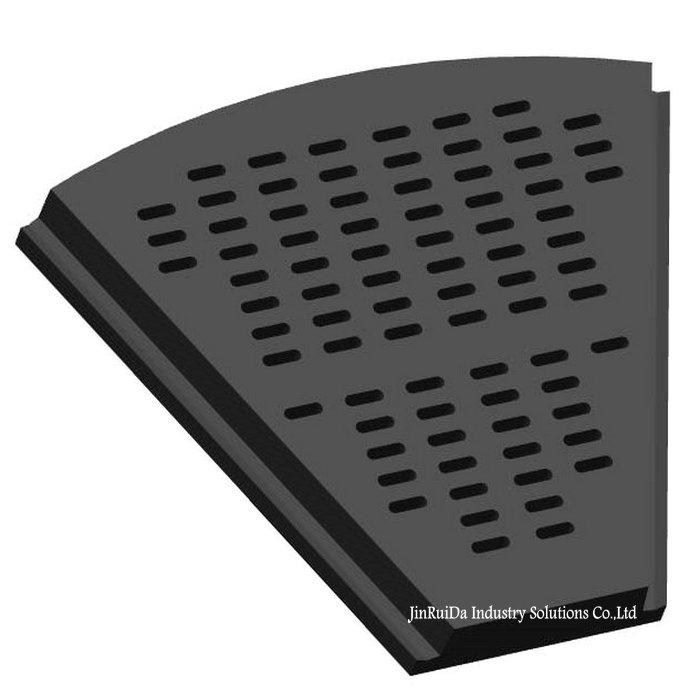

Rubber Screen Panels Plate Mats Deck Media is a kind of rubber lining plate. Embedded metal skeleton has the same specifications sheet, holes are uniformly distributed on the small noise, has good abrasion resistance. Is the main component of vibrating screen, Rubber Sieve Screen Plate mainly used for coal ore sorting grading, etc., Rubber Sieve Screen Plate are widely used in coal mine selection industry.

Structural Design:

The design of the structure includes: glue layer, skeleton layer, hole shape, bore diameter, and use the tension hook to connect with the screen machine, fixing method and so on.

Formula Design:

Wear resistant Rubber Sieve Screen Plate adhesive glue and glue brush cover. As the matrix material of polyester cord, the adhesive properties of similar polyester canvas. Therefore, choose polyester canvas glue for plate rub rub adhesive with good results. Rubber Sieve Screen Plate conditions require the use of it has good abrasion resistance, high strength, good elasticity, resistance impact and tear resistant properties. Therefore, determining the coverage formulation principle: high abrasion resistance, high strength, moderate elasticity, good processing performance.

Process study:

In order to meet the special use environment and complex load conditions of Rubber Sieve Screen Plate, the following are summarized: plasticization, mixing, rolling, pre forming, vulcanizing

Characteristic:

Wear resistant Rubber Sieve Screen Plate in screening equipment, compared with the metal sieve plate, there are several main features:

Highly wear-resistant Rubber Sieve Screen Plate can absorb the impact. so have excellent wear resistance. Under normal circumstances, wear resistant Rubber Sieve Screen Plate having a working life of more than 4-8 times higher than the metal plate.

Wear Rubber Sieve Screen Plate with low noise and less dust: On the basis of field investigation, machine wear rubber plate than metal plate can reduce the noise by 5-20 dB in the same screen, and can significantly reduce the dust flying, the workshop to get a quiet and clean working environment.

Wear Rubber Screen Panels Plate Mats Deck Media the proportion of small: easy to install, easy to disassembly and transportation. The weight of 1 square meters of Rubber Sieve Screen Plate of 15mm thickness is less than 15Kg, can reduce the weight of equipment itself, and a corresponding reduction in the power machine consumption.

Due to the structure of Rubber Sieve Screen Plate: which has the properties (i.e. mesh relaxation, under external force there is a periodic variation in small aperture), and the Rubber Sieve Screen Plate is an inverted cone, so it is not easy to hole blocking, has good self purification ability.

High screening accuracy of Rubber Sieve Screen Plate: because the Rubber Sieve Screen Plate is made of special shaped cutting tools at one time, so the size is accurate, with a Rubber Sieve Screen Plate can not have screening accuracy.

Rubber Materials Choose:

Rubber Screen Raw Materials Can Be Divided Into Natural Rubber And Synthetic Rubber. The Raw Material Of Rubber Screen Is Natural Wear-Resistant Rubber, Which Is Directly Extracted From Rubber Trees, Rubber Grass And Other Plants. After Processing, Rubber Raw Materials Have Special Properties Such As Elasticity, Insulation, Impermeability And Air. It Belongs To High Elastic Polymer. Synthetic Rubber Is Synthesized From Various Monomers. Rubber Screen Products Are Widely Used In All Aspects Of Industry Or Life.

♣ Natural Rubber NR

♣ Styrene Butadiene Rubber SBR

♣ Butyl Rubber IIR

♣ Hydrogenate Nitrile Rubber HNBR

♣ Ethylene Propylene Rubber EPDM

♣ Nitrile Rubber NBR

♣ Polyurethane Urethane PU Rubber