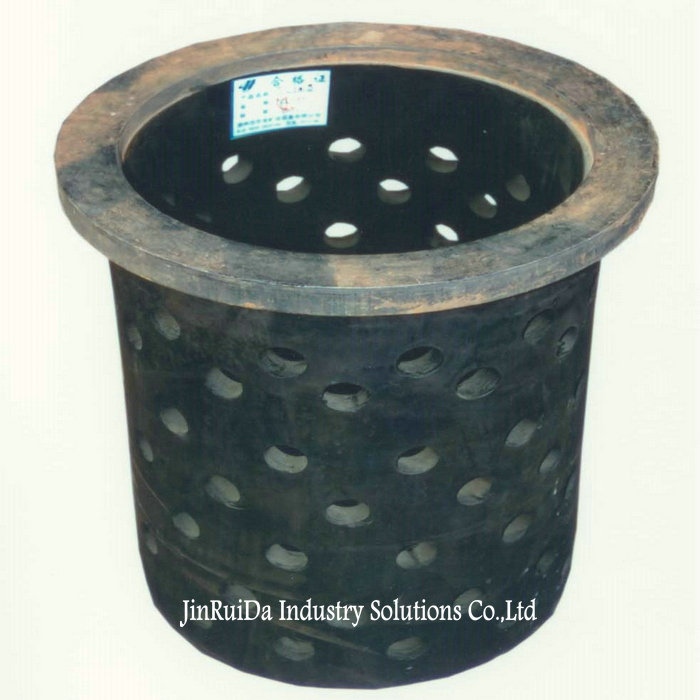

Description

Rubber Bearings Are Devices That Allow The Relative Motion Between Two Components To Be Restricted By Rotation Or Linear Motion. The Basic Purpose Of Bearings Is To Reduce Friction And Wear Between Rotating Parts In Contact With Each Other In Any Mechanism.

According To The Allowable Movement And Working Principle Of Bearings, Bearings Can Be Roughly Divided Into Several Categories. Each Type Of Bearing Has Different Uses. Bearings Are Made Of Various Materials, But Rubber Is a Widely Needed Material For Manufacturing Bearings.

It Has Been Proved That Rubber Is An Excellent Bearing Material, Especially When The Lubricant May Contain Abrasives. Rubber Used To Make Bearings Is a Tough Elastic Compound, Similar In Texture To Automobile Tyres.

Rubber Types For Manufacturing Bearings

Natural Rubber

Neoprene

Butyl Rubber (IIR)

Butadiene Rubber (BR)

Ethylene Propylene Diene Monomer (EPM, EPDM)

Rubber Bearing Types

Sliding And Laminated Elastic Rubber Bearings: Chloroprene Rubber And Natural Rubber Compound Bearings For Construction Industry. Laminated Rubber Bearings Provide The Simplest Isolation Method And Are Most Suitable For High Frequency Ground Motion.

High Damping Rubber Bearing (HDRB): This Is The Ideal Choice For Seismic Isolation. They Have Vertical Rigidity, Can Support Vertical Gravity Loads, And Have Lateral Flexibility, And Can Allow Large Horizontal Displacement. In Fact, In Earthquakes, The Ground Can Move Back And Forth On Isolated Foundations While Keeping Buildings “Still”. These HDRB Bearings Are Flexible And Have Energy Absorption Capacity. The Rubber Bearing Isolation System Partially Absorbs Some Seismic Input Energy. The Use Of Hdrb Rubber Bearings For Seismic Isolation Can Also Significantly Reduce Structural And Non-Structural Damage.

Low Damping Rubber Bearing: In The Isolation System, Different Types Of Rubber Bearings And Dampers Are Designed And Used. Low Damping Elastic Or Rubber Bearings Are Commonly Used In Buildings. These Rubber Bearings Are Widely Accepted For Their Long Life, Good Economy And Better Control Of Dynamic Characteristics.

Lead Rubber Bearing (LRB): Lead Rubber Bearing Is a Larger Laminated Bearing, Made Of Rubber Layer, Rubber Layer And Steel Layer Clamped Together, Bearing In The Middle Of a Solid Lead “Plug”. The Top And Bottom Of Lrb Are Equipped With Steel Plates, Which Are Used To Connect Bearings To Buildings Through Steel Plates. Foundation Was Established. The Design Of Lead Rubber Bearings Should Make The Bearings Rigid And Strong In Vertical Direction And Flexible In Horizontal Direction. Lead, Inserted As The Center Of Lrb, Consumes Energy From Earthquake And Rubber. Reinforced With Steel Plates, It Helps To Provide Stability, Support Structure And Isolate Vibration.