Description

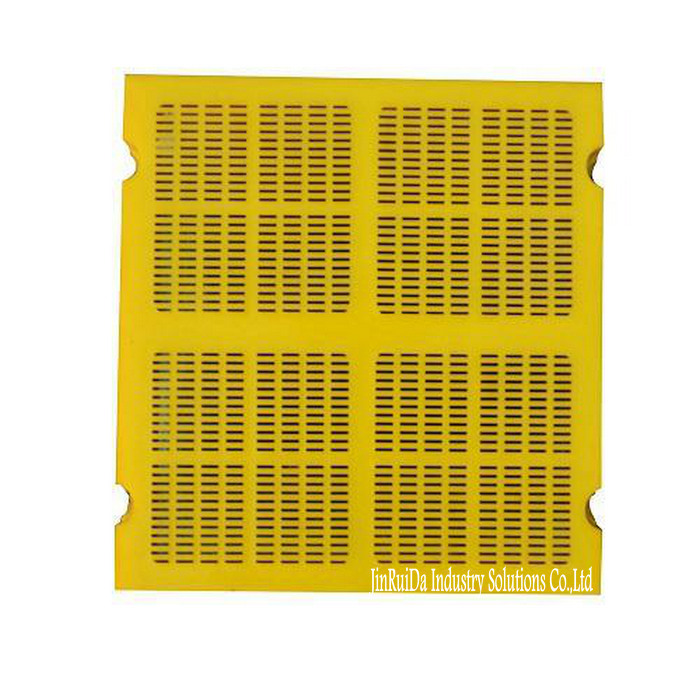

Polyurethane Screen Is a Polyurethane Plate With Holes Made Of Wear-Resistant Polyurethane Material. Our Company Also Produces Polyurethane Fine Mesh For High Frequency Vibration Screen. Similar To Rubber Screen, It Can Effectively Replace Metal Screen.

It Has The Characteristics Of Wear Resistance, Corrosion-Free And Self-Cleaning. Conical Mesh Can Improve Efficiency, Reduce Noise And Make Work More Comfortable. The Advantages Of Working Under Wet Working Conditions Are Particularly Prominent.

Polyurethane Screen Panels Mesh Mats Deck Media Bends is applied in hydropower station, building materials and other metal mining industry

♠Wide scope of application

♠Professional, more applicable

♠Suitable for any type of vibrating screen machine and can be manufactured by measuring machine

One kind of reticulated product produced with polyurethane elastomer as raw material.

The shape of the Polyurethane Sieve Plate: slit, rectangle, round and square

Polyurethane Screen Panels Plate Mats Deck Media Application Industries: coal washing plants, coking plants, mines, power plants, dredging company, metallurgy, petroleum, petrochemical and other industries.

Polyurethane Sieve Plate Application equipment: vibrating screen

Size 3mm Hole x 2040 mm Length x 500 mm Wide x 30mm thickness,

Size 4.5mm Hole x 2040 mm Length x 500 mm Wide x 30mm thickness

No.1, Working Principle :

♠Polyurethane is active elastomer materials.

♠When Polyurethane Sieve Plate is subjected to external force, the polyurethane shape changes later than external force time.

♠So that It can turn most of external force into polyurethane sieve plate Heat. And send heat out.

♠The rest of the external forces bounce back to the transport medium.

♠So as to achieve the role of wear-resistant and impact resistance.

♠So We usually choose polyurethane sieve plate as the best choice in the wear resistant industry.

No.2, Properties Characteristics :

♣High wear resistance, long service life, the wear resistance is 3~5 times of Wear steel sieve plate , more than rubber sieve plate

♣The polyurethane sieve plate maintenance workload is small, Polyurethane sieve is not easy to damage, long service life, so it can greatly reduce the amount of maintenance and maintenance downtime losses

♣The total cost of Polyurethane Sieve Plate is low, although Price of the Polyurethane Sieve Plate is Twice of the stainless steel plate at the same size (area), but the Polyurethane Sieve Plate life is 3~5 times of the stainless steel plate, So that reduce the time and cost of maintenance and replacement of Sieve Plate, so the total cost is not high, but also very economical.

♣Polyurethane Sieve Plate moisture resistant performance is good,:Under the working conditions of water and oil as the medium, the friction coefficient of Polyurethane Sieve Plate is very low, which is more conducive to screening and improving the screening efficiency.And avoid the adhesion of damp particles, At the same time, because of the decrease of the friction coefficient, the wear is reduced and the service life is improved

♣Corrosion resistance, non flammable, non-toxic, tasteless

♣Because the Polyurethane Sieve Plate design is reasonable, the sieve plate manufacturing technology is unique, the limiting size of the particles will not block the sieve

♣Polyurethane Sieve Plate has good vibration absorption performance, noise elimination ability, can reduce noise, and can make the medium in the process of vibration is not easy to break

♣Because polyurethane has the characteristics of two times vibration, the Polyurethane Sieve Plate has self-cleaning function, so the screening efficiency is high

♣Energy saving and consumption reduction, the proportion of Polyurethane Sieve Plate is small, and the Polyurethane Sieve Plate is much lighter than the same size steel screen, thus reducing the burden of screening machine, saving power consumption, and prolonging the service life of the screening machine

Polyurethane Sieve Plate Be Made Of High Quality Polyurethane And Good Tensile Embedded Metal Skeleton. Polyurethane Sieve Plate Combined With Wear Resistance Polyurethane And High Tensile Strength Steel Frame Framwork , Polyurethane Sieve Plate Can Be Good Used In Separating And Mining Screening Industry.

No.3, Connection Types:

As Similar As Polyurethane Dewatering Screen, Polyurethane Sieve Plate Connection Types As Below

♠Bolts Connection Polyurethane Sieve Plate

♠Mosaic Connection Polyurethane Sieve Plate

♠Press Bar Connection Polyurethane Sieve Plate

♠Hook Connection Polyurethane Sieve Plate

So Many Connection Types Polyurethane Sieve Plate Can Be Used For Different Machines Applications. Polyurethane Sieve Plate Is The Most Versatile And Cost Effective Modular System.

No.4, Specifications

♣Polyurethane Sieve Plate Material: Polyurethane , Metal Frame.

♣Polyurethane Sieve Plate Thickness: 10mm – 100mm.

♣Polyurethane Sieve Plate Aperture Type: Square, Rectangular , Round.

♣Polyurethane Sieve Plate Aperture Size: 2mm – 80mm.

No.5, Features :

♥Polyurethane Materials For Wear Resistance.

♥Self-Cleaning Apertures Reducing Pegging And Blinding.

♥Wide Range Apertures Suit Most Applications.

♥Various Panel Sizes To Suit All Vibrating Screens.

♥Different Connection Type For Easy Installation And Replacement.

♥High Screening Performance.

♥Low Noise.

♥Long Service Life And Durable.

No.6, Applications :

The Polyurethane Sieve Plate Can Fit Various Vibrating Screens. It Is Widely Used In Various Applications.

♦Steel Plants.

♦Mining Industry.

♦Cement Plants.

♦Mineral Industry.

♦Power Plants.

♦Coal Washing.

♦Sand, Gravel Separating And Screening.

No.7, Scope

(0.1mm – 170mm) Polyurethane Sieve Plate can be applied to the screening of various materials, regardless of dry screening, wet screening, does not affect the screening efficiency

(0.5m – 3mm) Polyurethane Sieve Plate can be applied to dewatering and stripping sieves, which fully shows the superiority of the Polyurethane Sieve Plate surface

♣water resistance,

♣Corrosion resistance,

♣Aging resistance,

♣Easy to change and maintain

♣Polyurethane density is small (1.32kg/ m 3),

♣Light in weight from metal screens,

♣Can reduce production unit consumption,

Therefore, the Polyurethane Screen Panels Plate Mats Deck Media can adapt to the large-scale development requirements of screening machine